|

CENSTAR SCIENCE & TECHNOLOGY CORP., LTD

|

| Payment Terms: | T/T,L/C,D/A,D/P,WU,Paypal,Money Gram |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Censtar is a fuel dispenser suppliers established in 1992, located in Zhengzhou City, Henan province, central China.

758 employees and possesses 80000M2 land, with a fixed asset of 800 million RMB. censtar

Annual production Capacity reaches 100,000 nozzles of Fuel Dispenser.

Main products as Fuel dispensers, Automatic Tank Gauge System, Petrol station management system and Petrol stations IC card management system etc.

It is the first and sole dispenser pumps suppliers company that reaches annual output and sales more than 100,000 nozzles of Fuel Dispenser. Its production capacity ranks No. 1 in China and third in the world.

For 17 consecutive years, Censtar keep the No. 1 position of output and sales of fuel dispenser suppliers in China.

Censtar is a dispenser pumps suppliers focus on ensuring quality of care to our clients by placing their needs at the forefront of what we do.

Our Mission is a best diesel pump manufacturers to provide complete Equipment Solutions to Retail Petroleum Industry.censtar

Service and quality is what we sell, peace of mind is what you buy.

we are seeking global co-operation agents for our products.

Vane Pump

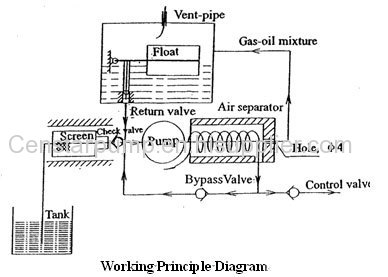

Fuel dispenser automatic verification system, through the vane type pump magnetostrictive liquid level sensor and the realization of the embedded platinum resistance thermometer liquid level height and standard metal gauge temperature vacume pump automatic data nozzle pump collection, and complete the metal gauge standard capacity value calculation.

a. The rotor of the pump is

rotated clockwise by the motor, and the vanes are rotated together with ring in

the same direction. The rotor and the casing are eccentric with each other.

Because of the eccentricity, the volume enclosed in the rotor, vane and inside

wall of the casing is changed as the rotor rotates, vane type pump and the oil

is moved consequently.

b.

A strainer is installed to the suction to prevent foreign

substances from entering the pump and piping, and a check valve is installed to

prevent the oil in the pump from returning to the tank. c. The oil sent out of

the pump is sent to air separator. Because of the flow guide, the oil is sent

along the casing of the air separator in the method of spiral mode of motion.

The low density gas-oil mixture is sent through the center(Hole, φ4 )of

discharge header to the normal pressure chamber.

d. The separated air is released

through vent-pipe from the top of the atmospheric chamber into the

atmosphere.

e. The oil

discharged through the φ4 hole accumulates in the atmospheric chamber.

If the oil reaches a certain level, the float is floated to open the valve, then

the oil is returned to the suction side.

f. The control valve consists of

main valve and auxiliary valve. The main valve on the discharge side is kept

open by the oil pressure while the oil is nozzle pump being supplied. When the

nozzle is closed , this main valve is closed automatically to prevent the oil in

the hose and flow meter from flowing back. This main valve also holds the oil

pressure in the hose and flow meter while the operation is stopped to protect

the flow meter from being rotated when the oil is supplied next time.

g. When the pressure rises to a

certain value due to change of ambient temperature, the auxiliary valve vane

type pump opens to vacume pump release an abnormal pressure caused by the

thermal expansion of oil.

h. The discharge side of the

casing is equipped with nozzle pump a bypass valve which is used to circulate

the oil through the pump when the nozzle is closed or the oil is supplied at a

low speed. The discharge pressure can be adjusted with a spring.

| Adjustment of set pressure of pump | |

| If the discharging flow rate is too low

because of higher suction head and longer piping, etc., and the discharge

pressure of pump is unstable, the discharge pressure(the nozzle is closed) and

inlet vacuum pressure(the nozzle is kept open) must be inspected. There are

1/4b. When installing or dismantling pressure gauge and vacuum pressure gauge,

stop the pump. The set pressure of vacume pump has been adjusted to 0.18~0.20Mpa

with the nozzle closed when the pump left factory. If the measured pressure does

not according with the set pressure and the adjustment of bypass valve is

needed, please adjust the bypass valve when the pump is not rotated. 1) Loose cap nut. 2)Adjust the set pressure by turning the adjusting bolt: ·Turning clockwise: set pressure heightened. ·Turning counterclockwise: set pressure lowered. 3) After adjusting set pressure, tighten cap nut. 4) Take care not to screw the adjusting bolt excessively to lock valve. If the valve is locked. |

Gear Pump

Gas pumps parts is the energy source of Fuel Dispenser. Censtar pump parts and service, by referring to European and American advanced technology and by adopting international standards of OIMLR117 and OIMLR118, developed GP03 gear type pump and was awarded patents for it.

The pump parts and service can be sucked and delivered through the engagement and disengagement of the gear teeth. See Fig. 2.1.3. When the internal gear is rotated clockwise, the gas pumps parts external gear is rotated together in the same direction. Because of the eccentricity, the volume enclosed between the internal gear and the external gear type pump is changed as the gear rotates, thus making oil to be delivered consequently

Pump parts and service compact structure, easy installation and maintenance, low noise, smooth operation, low fault rate and long service life;Built-in non-return valve, switch valve, relief valve, vacuum valve, gas pumps parts can be more than with oil gun come on at the same time, used for gasoline, kerosene, diesel oil, etc., gear type pump can prevent gas, avoids the gas can't oiling phenomenon.